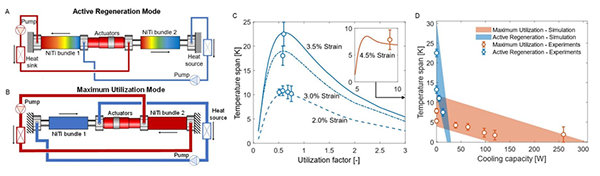

Fig. The multimode elastocaloric cooling system. (A) active regeneration mode. (B) maximum utilization mode. (C) multimode operation at respective optimum utilization factor. (D) performance map.

Funded by the National Natural Science Foundation of China (grant 51976149 and 51721004), Associate Professor Suxin Qian from School of Energy and Power Engineering, Xi’an Jiaotong University made an advancement in elastocaloric cooling with an international team led by Prof. Ichiro Takeuchi from University of Maryland, College Park. The progress was published as a research article entitled “high-performance multimode elastocaloric cooling system” in Science on May 19, 2023. Link: http://www.science.org/doi/10.1126/science.adg7043

Refrigeration accounts for 7.8% of global carbon emissions. In refrigeration systems, 20% of carbon emission is due to leakage of high GWP refrigerants throughout their service life. Therefore, elastocaloric cooling with zero GWP provides a promising alternative for carbon neutrality in the refrigeration sector. Elastocaloric cooling leverages the latent heat from the nominally reversible martensitic phase transition induced by uniaxial stress. It is known for its high energy and cooling power density, high material coefficient of performance, and easiness of recycling. Since its debut in 2014, elastocaloric cooling systems are mainly based on either the single-stage cycle or the active regeneration cycle. The single-stage cycle can produce high cooling power but is limited by temperature span. On the contrary, the active regeneration cycle can achieve high temperature span yet with deficient cooling power. How to achieve both high cooling power and temperature span remains a key challenge before commercializing this technology.

To solve this problem, a new system architecture was proposed that features both the active regeneration cycle and the single-stage cycle. The two modes can be easily switched from one to the other by the fluid network (Fig. A and B). By switching between two modes, the range of the optimum utilization factor was significantly extended. The optimum utilization factor of the active regeneration mode is usually around 0.6 because a substantial amount of elastocaloric heat remains inside the material to maintain the necessary temperature gradient. However, this optimum utilization factor can be extended tenfolds in the single-stage operation, i.e. maximum utilization factor, where most of the elastocaloric heat is extracted from the material (Fig. C). With the extended utilization factor, the new system achieved 22.5 K temperature span and 260 W cooling power, which were significantly improved compared to the 8 K temperature span and 30 W cooling power in each standalone mode (Fig. D). Therefore, the new system architecture facilitates high-efficient operation in real-world scenarios where the operating condition and load vary considerably.

This work was the first paper in Science about elastocaloric cooling systems. Hopefully, the proposed multimode concept and novel system architecture inspired by this concept could promote future research and commercialization of not only elastocaloric cooling but caloric cooling in general.

Add: 83 Shuangqing Rd., Haidian District, Beijing, China

Postcode: 100085

Tel: 86-10-62327001

Fax: 86-10-62327004

E-mail: bic@donnasnhdiary.org

京ICP备05002826号 文保网安备1101080035号 Copyright 2017 NSFC, All Right Reserved